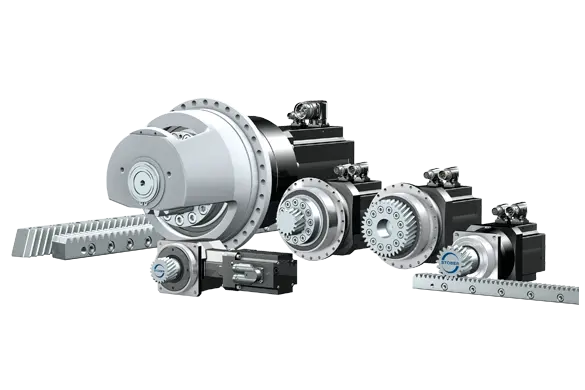

From full rotation into linear motion: Rack and pinion drives with synchronous servo motors.

With the innovative system concept for rack and pinion drives, STOBER has developed a compact, easy-to-use system with process reliability that is precisely tailored to the application areas of machine tools, automation and robotics.

By combining them with our planetary or helical bevel gearboxes and STOBER servo motors, you get the benefit of extremely compact, highly dynamic drive solutions.

-

Rack and pinion drive with

EZ motor - ZV…EZ: High flexibility for automation and robotics

- ZR…EZ: High speed due to high feed velocities

- ZTR…EZ: High performance for demanding drive concepts

- ZTRS…EZ: High force for maximum power density

Our rack and pinion drives are versatile, ready-to-install solutions that are adapted to meet the various requirements in terms of load capacity and precision.

Rack and pinion drives with synchronous servo motors – All pinion designs are available in combination with STOBER planetary gearboxes, and the ZV series can also come with helical bevel gearboxes.

Another plus is that our gear racks with twice the bores are perfectly coordinated with STOBER drives.

All STOBER EZ series motors can be directly attached to the gearbox in any size you need – without any adapters.

Omitting the motor adapter means that you benefit from lower mass moments of inertia so you get the most out of the dynamics of your drive.Rack and pinion drives with synchronous servo motors – from the ZV series mean maximum flexibility when it comes to possible combinations.

The rack and pinion drives can be mounted either on the planetary gearboxes from the P series, on the very economical PE series or on STOBER helical bevel gearboxes from the K, KS or KL series.

No matter which drive solution you require, you will always benefit from a perfectly matched, powerful geared motor equipped with top-quality helical gearing.

The rack and pinion drives of the ZR series feature large, helical pinions with a bolt circle, which allow high feed velocities.

By combining them with a PH series planetary gearbox and an EZ series synchronous servo motor, you get a high-performance geared motor ideal for any kind of drive solution with the highest requirements for rigidity, precision and reliability.

The very precise and also very powerful ZTR series features small pinion diameters and high linear rigidity and requires lower torques.

The pinions with the welded screw flange can be easily mounted and dismounted. The ZTR series is therefore ideal for feed axes of machine tools where the supporting bearing holder is an interfering contour. This means gantry machines, vertical and horizontal lathes or milling and drilling centers.

By combining the series with PH or PHV series planetary gearboxes and an EZ series synchronous servo motor, you get a high-performance geared motor ideal for any kind of drive solution with the highest requirements for rigidity, precision and reliability.

Developed by STOBER, the bolted supporting bearing holder with stiffening ribs on the inner contour makes it possible to use the full gear torque in a rack and pinion drive for the first time. This also optimizes the power density and rigidity.

ZTRS, Rack and pinion drives with synchronous servo motors, is ideal for feed axes of machine tools, laser machines and highly dynamic and precise handling systems.

By combining the series with PH, PHV or PHQ series planetary gearboxes and an EZ series synchronous servo motor, you get an extremely compact, highly dynamic drive with STOBER’s typical top-quality helical gearing and very high torsional and tilting stiffness.

Do you design gravity-loaded axes? Learn more about our rack and pinion drives with synchronous servo motors and redundant brake.

0 ZVEZ rack and pinion drive technical data

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 4 mm

- Number of teeth: 16 – 25

- Acceleration feed force: 0.8 – 11 kN

- Permitted feed velocity: 0.1 – 4.5 m/s

- Linear backlash: 8 – 44 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 3 mm

- Number of teeth: 16 – 25

- Acceleration feed force: 0.48 – 6.1 kN

- Permitted feed velocity: 0.17 – 4.5 m/s

- Linear backlash: 40 – 83 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 4 mm

- Number of teeth: 18 – 25

- Acceleration feed force: 1.3 – 11 kN

- Permitted feed velocity: 0.08 – 3 m/s

- Linear backlash: 37 – 44 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 mm

- Number of teeth: 16 – 20

- Acceleration feed force: 0.64 – 2.7 kN

- Permitted feed velocity: 0.21 – 1.7 m/s

- Linear backlash: 99 – 123 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 4 mm

- Number of teeth: 18 – 25

- Acceleration feed force: 0.91 – 15 kN

- Permitted feed velocity: 0.04 – 3.4 m/s

- Linear backlash: 12 – 111 μm

Find your right fit!

ZREZ rack and pinion drive technical data

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 4 mm

- Number of teeth: 26 – 40

- Acceleration feed force: 0.49 – 16 kN

- Permitted feed velocity: 0.16 – 6 m/s

- Linear backlash: 10 – 56 μm

Find your right fit!

ZTREZ rack and pinion drive technical data

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 8 mm

- Number of teeth: 12 – 32

- Acceleration feed force: 1.9 – 67 kN

- Permitted feed velocity: 0.1 – 4 m/s

- Linear backlash: 4 – 44 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 5 – 6 mm

- Number of teeth: 16 – 19

- Acceleration feed force: 32 – 67 kN

- Permitted feed velocity: 0.12 – 0.39 m/s

- Linear backlash: 42 – 44 μm

Find your right fit!

ZTRSEZ rack and pinion drive technical data

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 10 mm

- Number of teeth: 15 – 32

- Acceleration feed force: 2.8 – 94 kN

- Permitted feed velocity: 0.12 – 4 m/s

- Linear backlash: 7 – 70 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 8 – 10 mm

- Number of teeth: 15 – 19

- Acceleration feed force: 107 – 126 kN

- Permitted feed velocity: 0.12 – 0.26 m/s

- Linear backlash: 69 – 70 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 5 – 10 mm

- Number of teeth: 15 – 20

- Acceleration feed force: 26 – 94 kN

- Permitted feed velocity: 0.13 – 0.49 m/s

- Linear backlash: 44 – 70 μm

Find your right fit!

0 ZV…EZ rack and pinion drive features

- To the features of ZV rack and pinion drives

- To the features of P gearboxes

- To the features of EZ motors

- To the features of ZV rack and pinion drives

- To the features of PE gearboxes

- To the features of EZ motors

-

ZV Rack and pinion drives with synchronous servo motors – feat. KS gearbox feat. EZ motor …

- To the features of ZV rack and pinion drives

- To the features of KS gearboxes

- To the features of EZ motors

- To the features of ZV rack and pinion drives

- To the features of KL gearboxes

- To the features of EZ motors

- To the features of ZV rack and pinion drives

- To the features of K gearboxes

- To the features of EZ motors

0 ZR…EZ rack and pinion drive features

- To the features of ZR rack and pinion drives

- To the features of PH gearboxes

- To the features of EZ motors

0 ZTR rack and pinion drive features

- To the features of ZTR rack and pinion drives

- To the features of PH gearboxes

- To the features of EZ motors

-

ZTR rack and pinion drive with PHV gearbox feat. EZ motor …

- To the features of ZTR rack and pinion drives

- To the features of PHV gearboxes

- To the features of EZ motors

0 ZTRS rack and pinion drive features

- To the features of ZTRS rack and pinion drives

- To the features of PH gearboxes

- To the features of EZ motors

- To the features of ZTRS rack and pinion drives

- To the features of PHQ gearboxes

- To the features of EZ motors

- To the features of ZTRS rack and pinion drives

- To the features of PHV gearboxes

- To the features of EZ motors

- Portal milling

- Horizontal machining units

- Pick and place

- Laser cutting

- Tube bending

- Sheet metal bending

- 7th axis

- Vertical turntables

- Horizontal turntables

We get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn more| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Catalog Rack and pinion drives with synchronous servo motors | 04 | 443286 | 2024 10 | EN | 12.59 MB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Operating manual KL10 - KL20 gear units and geared motors | 00 | 443363 | 2023 07 | EN | 1.74 MB |

| Operating manual KS40 - KS70 gear units and geared motors | 00 | 443362 | 2023 07 | EN | 1.74 MB |

| Operating manual P23 - P93 gear units and geared motors | 00 | 443356 | 2023 07 | EN | 1.57 MB |

| Operating manual PHV94-PHV104 gear units geared motors | 00 | 443355 | 2023 02 | EN | 1.66 MB |

| Operating manual PH33-PH83 PH94-PH104 gear units geared motors | 00 | 443354 | 2023 02 | EN | 1.70 MB |

| Operating manual PHQ43-PHQ83 PHQ94-PHQ124 gear units geared motors | 00 | 443353 | 2023 02 | EN | 1.74 MB |

| Operating manual PE22 - PE52 gear units and geared motors | 00 | 443252 | 2021 03 | EN | 775.46 KB |

| Operating manual K1 - K10 gear units and geared motors | 00 | 443364 | 2023 07 | EN | 3.06 MB |

| Operating manual gear racks | 00 | 443392 | 2024 04 | EN | 1.75 MB |

| Safety instructions for synchronous servo motors synchronous servo geared motors | 00 | 443104 | 2018 07 | EN | 74.66 KB |

| Operating manual EZ EZHD EZHP EZS EZM synchronous servo motors | 01 | 443032 | 2019 05 | EN | 441.75 KB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Lubricant fill volume | 17 | 441871 | 2023 10 | EN | 2.18 MB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Certificate Free of CCC | 35 | 442072 | 2025 04 | EN | 261.03 KB |

| EU declaration of conformity synchronous servo motors and synchronous geared motors ED EK EZ | 02 | 443089 | 2024 03 | EN | 73.57 KB |

| UK declaration of conformity synchronous servo motors and synchronous servo geared motors EZ ED EK LM | 00 | 443297 | 2021 10 | EN | 71.46 KB |

| Certificate UL - cURus synchronous servomotors EZ EZS EZM EZHD EZHP | 00 | 443097 | 2016 12 | EN | 1.44 MB |

Take advantage of the expertise of our application engineers in the Sales Centers or contact our first level support.

Technology ConsultingSERVOsoft®

With SERVOsoft®, you have a tool at your fingertips that lets you design your drive systems with precise scaling in just a few steps. Electrical as well as mechanical. And simple and fast at the same time.

SERVOsoft®With the intuitive STOBER product configurator, you can filter, compare, save and share the right drive solutions with ease.

STOBER ConfiguratorAre you looking for CAD data? With the STOBER CAD tool, the drawings you need are ready for download in just a few clicks.

STOBER CADSTOBER is present in over 40 countries worldwide with 11 subsidiaries and 80 service partners. No matter where, no matter when, we’re always at your service and on the move!

Service NetworkDo you need competent help with replacement parts, replacement drives, repairs and retrofitting? Feel free to contact us! We also offer a 24-hour hotline for urgent cases.

Replacement & RepairFor us, TEAMWORK is a huge priority.

“At WINDMÖLLER & HÖLSCHER, collaborative partnership and trust are huge priorities. With our manufacturer STOBER, we have a strategic partner who also lives these by principles.”

– Christian Klein, Strategic Purchasing, WINDMÖLLER & HÖLSCHER KG

Available worldwide.

The manufacturer STOBER is represented in over 40 countries worldwide with 12 subsidiaries and 80 service partners.

This might also interest you

6th Generation Drive Controllers

Tailor-made for any kind of drive task – with four mutually combinable SC6, SI6, SD6 and SB6 series, STOBER always has the right controller on hand.