Virtual Lifetime

Condition Monitoring.

Predictive Maintenance.

Drive Optimization.

STOBER Virtual Lifetime – the feature for Predictive Maintenance of your

geared motors. For a long, efficient service life!

- Monitor the geared motors of the drive system.

- Calculate the service life using a model-based analysis method.

- Detect the actual load situation of the system.

- Increase quality and profitability.

Predictive Maintenance in the system

- For all STOBER geared motors in combination with 6th generation drive controllers.

- Simple plug and play.

- Straightforward handling without complex analysis.

- Act efficiently instead of interpreting.

Available worldwide.

STOBER is present in over 40 countries worldwide with 12 subsidiaries and 80 service partners.

CONDITION MONITORING

Precisely detect drive conditions.

- Software and encoder-based, without external sensors.

- Without additional wiring or additional license-based software.

- Without data preparation after the fact.

PREDICTIVE MAINTENANCE

Maintain your system proactively.

- Easy handling without expert know-how.

- Act efficiently instead of interpreting.

- Minimize downtimes and increase productivity.

Model-based approach

- Actual values: measurement of speed, torque, temperature.

- Synchronize with reference values from the STOBER geared motor database.

- Calculate the predicted remaining service life with physical technical equations.

Life performance indicator

- Value for the calculated service life of a geared motor: 0 – 100%.

- > 90%: recommendation for exchange.

- Output in the software of the drive controllers or via a higher-level controller.

DRIVE OPTIMIZATION

Manage your system sustainably.

- Analyze load situations in the application.

- Detect anomalies, optimize operating states.

- Increase competitiveness.

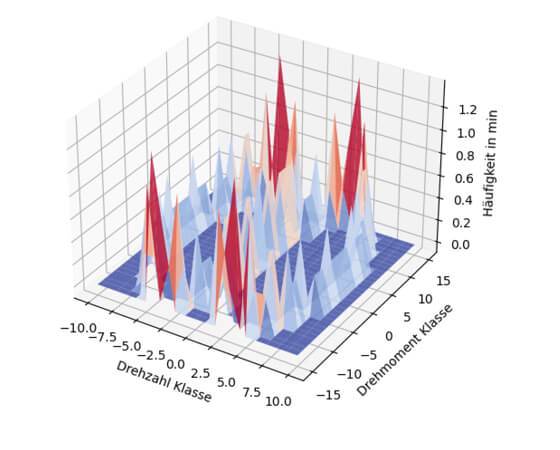

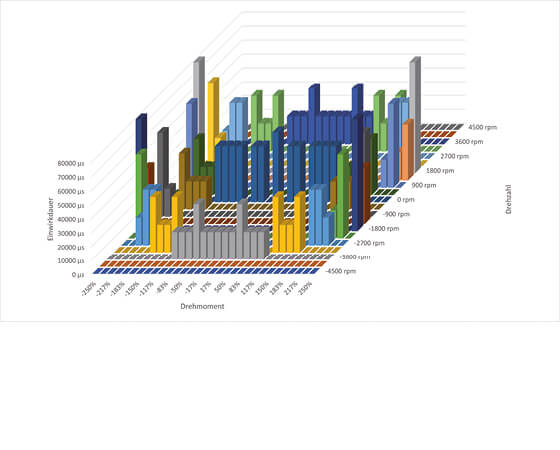

Load matrix

- Continuous documentation of the cumulative load condition of the drive system over the entire operating time.

- Database for recording real-world load situations.

- Export Virtual Lifetime data as a JSON or CSV file.

- Maximum transparency and unrestricted access to the measurement data of the drive system.

The best long-term plan.

“With the STOBER “Virtual Lifetime,” the new feature for Predictive Maintenance, we offer our customers three powerful functions at once for monitoring the drive train. These include Condition Monitoring, Predictive Maintenance, and the ability to optimize drives in real-world applications. The license-free approach is particularly noteworthy here, which functions without external sensors and independently of the controller. It’s simply smart – which is what you expect of products from our company!”

– Markus Graf, Chief Sales Officer (CSO), STOBER