Planetary Gearbox Design with the FVA-Workbench

Reliable. User-Friendly. Efficient: Planetary Gearbox Design with the FVA-Workbench.

STOBER relies on the FVA-Workbench for dimensioning and verification of their drive systems. The calculation and simulation software allows STOBER engineers to develop their innovative transmission solutions more quickly and efficiently. The result: higher quality products.

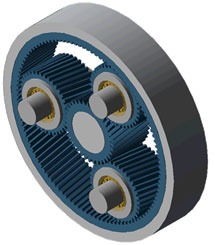

STOBER uses the FVA-Workbench for dimensioning and verification of their standard drives as well as client-specific applications and custom gearboxes. A wide range of design goals are considered, such as load capacity, vibration, power loss, and efficiency. Designing modular planetary gearboxes involves the planetary gear stages of an entire series, consisting of different dimensions and gear ratios. This requires mass calculations that would be very time-consuming without suitable software. With the FVA-Workbench’s integrated scripting feature, these tasks can be implemented quickly and without special programming knowledge.

Scripting makes it easy to perform mass calculations

For the design of planetary gears, STOBER’s development team first considers the macrogeometry taking various restrictions into account, such as installation space, manufacturing, and cost-effectiveness. Characteristics such as load capacity, power loss, or vibration are largely influenced by the gear geometry. This development step is crucial for the excellent operating characteristics of STOBER drives. Customer-specific requirements for planetary gear design can also easily be included.

The ability to perform mass calculations during gearbox design helps engineers determine optimal gearbox solutions. In the FVA-Workbench, the integrated scripting feature is used to perform mass calculations. As preparation, the parameters to be varied (such as the helix angle, module, center distance, addendum modification, and load information) are pre-defined in an Excel spreadsheet. The script then prepares a calculation plan and executes the mass calculations for each variant one-by-one.

Scripting uses a pre-defined FVA-Workbench model, manipulating variables for each calculation. This makes it possible to automatically calculate several thousand variants in a short time. The FVA-Workbench’s excellent HTML-based reporting feature is used to evaluate the calculations. This format allows the engineer to select the results to be evaluated. The data can also be visualized and saved. This makes searching through cluttered PDF reports a thing of the past. The scripting feature also makes it easy to export results in native Excel formats for further evaluation.

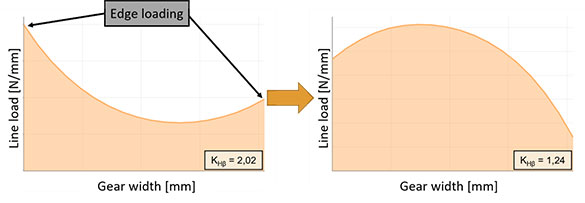

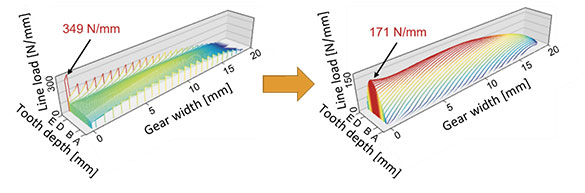

The microgeometry is designed similar to the macrogeometry. Flank and profile modifications are varied, pre-defined in an Excel spreadsheet, read by the FVA-Workbench, and processed by the scripting tool. Figure 3 shows an example of two calculation variants from an FVA-Workbench report, with and without flank modification. Bearing and component stiffnesses can also be included in the calculations.

The FVA-Workbench includes several options for considering the planet carrier stiffness. Early in the design phase, the approximate planet carrier geometry can be predefined, exported via CAD interfaces, and configured for production. Once the finished planet carrier is available as a CAD component, it can be imported into the FVA-Workbench and meshed using internal tools. No specialist FE calculation knowledge is required, and comprehensive user guidance guarantees reliable results. The FE mesh can then be evaluated and optimized as necessary using FVA-validated methods. FE meshes can also be loaded from existing models.

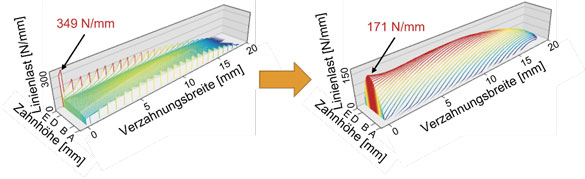

The FVA-Workbench can be used to evaluate the local pressure distribution, with clear 3D visualization. Figure 4 shows an example of the comparison of two calculation variants, with and without profile modification. In addition to the local load distribution, a number of other characteristics can be calculated in the planetary gearbox design software and used to make statements about the operating behavior of individual components as well as the entire system.

FVA-Workbench Planetary Gearbox Design: STOBER’s solution for reliable and efficient product development

What used to require serial control of individual calculation cores with in-house developed software now takes place completely within the FVA-Workbench. This has greatly simplified integration and maintenance of STOBER’s calculation landscape, allowing them to focus on their core business while also achieving performance gains in gear design. With its integrated scripting feature, the FVA-Workbench is perfect for designing entire modular systems. Powerful visualization and HTML-based reporting offer almost limitless possibilities for comparing individual calculation variants.

“With all the advantages the FVA-Workbench offers, it is also fun to use.“With all the advantages the FVA-Workbench offers, it is also fun to use.“

Hans Rollbühler, development engineer at STOBER Drive Technology

STOBER Drive Technology

STOBER has been developing and producing drive technology excellence since 1934. The company has around 800 employees at 12 international locations. The STOBER drive system consisting of gearboxes, motors and drive controllers has a modular design and is freely scalable – for tailor-made, compact and powerful machine concepts in a wide range of industries and markets worldwide. For machine manufacturers, this means: one partner, certified reliability, maximum availability.

FVA-Workbench

The FVA-Workbench is the leading software solution for the modeling, parameterization, and calculation of gear systems. With more than 50 years of research projects, Research Association for Drive Technology (FVA) develops and bundles the cumulative knowledge of the largest drive technology innovation network. An easy-to-use interface makes even the most demanding modeling easy and provides access to highly reliable results.

Learn more at: www.fva-service.de/en/