GUANDA International Machinery in Taiwan relies on a complete system from STOBER.

GUANDA International Machinery from Taiwan designs and develops machines for the steel construction industry, such as marking double T-girders with a laser for the construction sector or drilling for assembly work. In its systems, the manufacturer relies on drive technology from STOBER. The specialist supplied the entire system, including rack and pinion drives, synchronous servo motors, cables and drive controllers. Not to mention expertise. The global provider also wins over customers by being close at hand with its subsidiary in Taiwan. Another important aspect is the collaboration, which is always on equal footing.

The total package

Double T-girders, also called H-beams, are characterized by their high load-bearing capacity. This makes them excellent for the construction of buildings and bridges, which require strong, stable structures. GUANDA, headquartered in Taichung City on the west coast of Taiwan, develops machines for marking these stable elements with a laser or drilling bores for assembly. For this purpose, the machine manufacturer has 3-axis drilling centers and laser marking systems in its range. “The construction industry in Taiwan is a relatively traditional sector,” explains Tom Huang, Deputy Managing Director of GUANDA. “Our goal is to support customers from this industry with efficient and intelligent solutions.” The company has almost 30 years of experience in the construction sector. This enormous wealth of knowledge contributes to the development of the machines, which is exactly what makes them so competitive. And unlike their competitors, the manufacturer relies on PC-based solutions, not CNC-controlled ones.

“Currently, we are producing exclusively for the domestic market,” says Head of Production Eric Wu. But that will change starting in 2026. By then, the company will have moved into a new factory building with an area of around 3,000 square meters. Large-scale series production should be possible then, enabling them to deliver around the world.

Select local partners

When implementing these demanding special machines, the manufacturer relies on select partners. “It is important for us that we always work together as equals. This is only possible with companies that share a similar philosophy and the same values as us,” says Huang. That is why GUANDA relies on STOBER for all its drive technology needs. The drive specialist’s Taiwanese subsidiary is also located in Taichung City, just minutes away from GUANDA.

Together, the partners developed the prototype for a new 3-axis drilling center. “We offered comprehensive technology from a single source,” says Matthias Eberle, Director of Business Development Asia Pacific at STOBER. “As a rule, our customers care predominantly about precision. But the focus here is on a robust and thus long-lasting solution.” The goal was to implement perfect motion together with the customer. To that end, STOBER supported the machine manufacturer throughout the entire project.

Fast assembly

For axis motion, the drive specialist delivered its new rack and pinion drive with directly attached synchronous servo motors of the EZ series. STOBER exclusively uses case-hardened, smoothed pinions with the highest gearing quality at the output of the gear unit. “We now also offer the rack and pinion drive as a one-stop solution – that is, customized and as a complete package including the installation, design and system support,” Eberle explains.

STOBER offers its gear racks in various lengths and modules. This allows the drive specialist to tailor them precisely to the respective application. This component must not move when force is applied by the pinion. Suppliers usually ensure this by using dowel pins at both ends of the gear rack in addition to the pressing force provided by the screw fastenings. “However, this involves a considerable amount of work,” says Eberle. To ensure that the position is exactly right, the bores for the dowel pins must be made and then reworked with a reamer directly on the machine in the bolted-on state. This work is very laborious and time-consuming, especially for complex systems with various attachments. “Our solution eliminates the need for time-consuming pinning,” says Eberle. “We supply precision gear racks with double the bores. There is now a bore for a screw connection every 62.5 millimeters, instead of every 125 millimeters as usual.” This doubles the contact pressure of the gear rack on the machine body. Pinning is still possible thanks to the existing pin holes. This ensures the highest possible level of safety. Eberle adds, “Users also benefit from maximum ease of installation.”

Tailor-made for every drive task

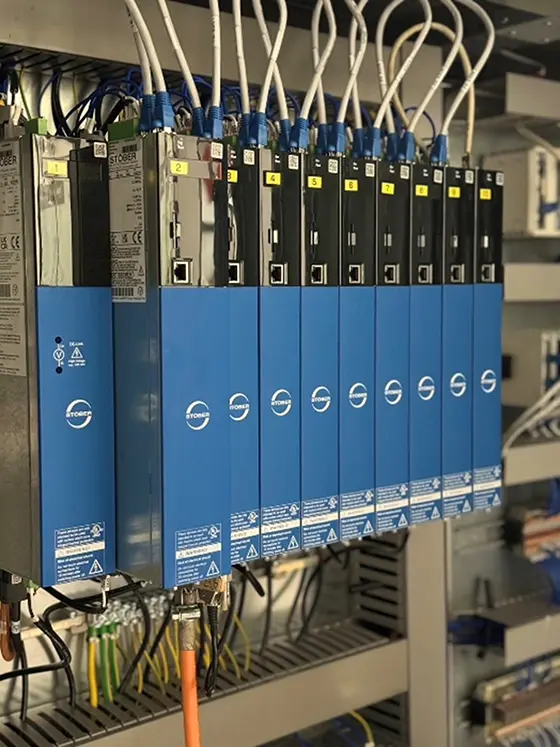

STOBER supplied controllers of the SI6 series to control the drives. The highly dynamic solution with a width of only 45 millimeters is designed as a multi-axis drive system. “The controller works invisibly and reliably in the background,” says the STOBER expert. “A single SI6 can control up to two axes, a clear space advantage.” By stringing together several devices, the number of axes to be controlled can be scaled individually. Quick DC-Link modules quickly and easily connect the individual controllers with each other and with the PS6 central supply module. As a result, there is no need for decentralized supply modules or fuses and cabling for each axis. This series achieves very short recovery times with fast set value changes and load jumps. The STO (Safe Torque Off) and SS1 (Safe Stop 1) safety functions are also integrated into the SI6, which are certified in this series for PLe, cat. 4 in accordance with EN 13849-1 and can be used without function tests that interrupt production. “Our SI6 drive controllers are available with the Ethernet-based EtherCAT fieldbus system or with PROFINET, for example. For communication with the KEBA control solution used at GUANDA, the drive controllers with the certified EtherCAT interface are used.”

In order to connect the drive controllers with the motors reliably, STOBER supplied its one-cable solution, which the drive specialist has further developed with encoder manufacturer HEIDENHAIN. The next generation is now on the market. Thanks to the future-proof HEIDENHAIN EnDatâ 3 protocol, the hybrid cable can reliably connect motors and drive controllers at a distance of up to 100 meters. Its special feature is that it transmits signals from the motor to the drive controller at a distance of up to 50 meters, without errors or expensive output chokes. “So instead of using two lines, one for transmitting encoder data, one for the electrical power, we use just one hybrid cable, which saves a significant amount of space,” explains Eberle. “Our customer receives a complete system consisting of synchronous servo motor, cable and the appropriate drive controllers.”

The same language

This perfectly coordinated system solution was ultimately the deciding factor for the machine manufacturer when choosing STOBER. This was topped off by expert engineering, dimensioning of the gear units and connection to drive controllers and controllers. The wealth of knowledge of the STOBER specialists in Taiwan was also important. “The physical proximity to STOBER Taiwan naturally helped during the collaboration, as did the good personal contact and excellent cooperation,” Wu says. “We trusted in STOBER for the entire duration of the project.” James Wu, Sales Director at STÖBER Taiwan, adds, “Medium-sized companies often get along well with other medium-sized companies. We speak the same language and have a similar understanding of many things, such as how we approach tasks and tackle challenges. For us, it is a given that we must always be available for our customers. We always communicate as equals, which is exactly why GUANDA feels comfortable with us.”

“We offered comprehensive technology from a single source. As a rule, our customers care predominantly about precision. But the focus here is on a robust and thus long-lasting solution. We now also offer the rack and pinion drive as a one-stop solution – that is, customized and as a complete package including the installation, design and system support.”

– Matthias Eberle, Director of Business Development Asia Pacific at STOBER

This might also interest you

6th Generation Drive Controllers

Tailor-made for any kind of drive task – with three mutually combinable SC6, SI6 and SD6 series, STOBER always has the right controller on hand.