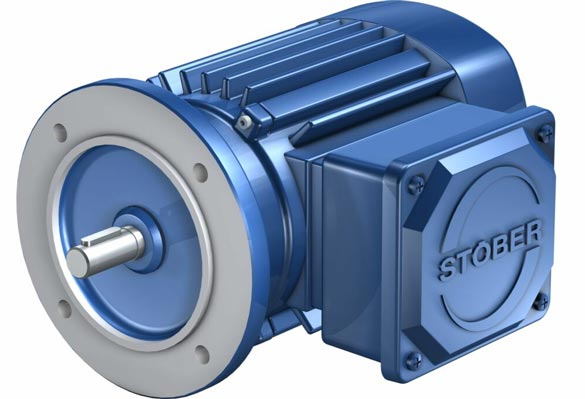

Asynchronous motors: An evergreen classic.

In the game for over 100 years, the classic asynchronous motor is still one of the most popular power transmission motors.

STOBER asynchronous motors are IE3-certified and therefore feature excellent energy efficiency and high profitability!

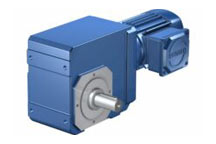

Another plus point is that these asynchronous motors are attached directly to STOBER gearboxes (helical, offset helical or helical bevel) as standard – without any interfering adapters. It’s an advantage in terms of compactness, efficiency and costs.

Designed as asynchronous squirrel-cage motors, STOBER asynchronous motors have amazingly good performance in a wide range of applications. This is because asynchronous motors cover so many kinds of applications – they are at home in conveyor systems, in pump drives and also in fans.

Focus on the highly efficient drive axis: STOBER asynchronous motors are IE3-certified in accordance with IEC 60034-30. Amazing premium efficiency. And as a result, especially profitable in terms of energy.

Due to its long-proven, simple and standardized design, the asynchronous motor can withstand particularly high loads. In addition, it is extremely robust and designed for continuous operation.

STOBER asynchronous motors are generally attached directly to the helical, offset helical or helical bevel gearbox without any interfering adapter. It’s a great benefit in terms of compactness, efficiency and costs.

You can also choose from multiple combinations of brakes, encoders and cable feeds – optimally matched to your individual requirements.

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Nominal torque: 0.82 – 291 Nm

- Nominal speed: 1400 – 1480 rpm

- Nominal power: 0.12 – 45 kW

- Nominal current: 0.35 – 83 A

Find your right fit!

- Energy efficiency classes:

- Europe: IE3 premium efficiency in acc. with IEC 60034–30–1

- USA: CC 301B in acc. with NEMA-C, EISA 2014

- Shaft:

- IEC design

- Cooling:

- Self-ventilation with a plastic fan wheel

- Forced ventilation; also as a retrofit kit

- Brake: Electromagnetic spring-loaded brake

- Encoder interfaces: Incremental or SSI (only together with forced ventilation)

- Terminal box: Convenient yet rugged design with integrated seal protection (IP 66) for safe motor connection

- Marks and test symbols:

- CE

- cURus

- EISA CC number including cURus (60 Hz, 265 V/460 V)

- Recommended drive controllers or inverters: Exceptionally efficient in combination with STOBER 6th generation drive controllers or 5th generation inverters

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Catalog STOBER compact | 06 | 442655 | 2024 10 | EN | 9.76 MB |

| Catalog Asynchronous Geared Motors IE3 | 03 | 443136 | 2022 11 | EN | 17.16 MB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Operating manual VEM asynchronous motors | 04 | 441750 | 2022 07 | EN | 6.77 MB |

| Operating instructions Brakes for Asynchronous Motors IE2 | 04 | 442015 | 2014 07 | EN | 944.54 KB |

| Operating manual asynchronous motors | 01 | 442577 | 2014 07 | EN | 331.55 KB |

| Operating instructions STÖBER Incremental Encoders | 02 | 442025 | 2014 07 | EN | 1.54 MB |

| Operating instructions Brake accessories for Asynchronous Motors | 03 | 442020 | 2014 07 | EN | 458.09 KB |

| Safety instructions for electrical equipment (VEM) | 01 | 441752 | 2018 10 | EN | 477.20 KB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Connection plan asynchronous motors with connector box | 06 | 441431 | 2018 01 | EN | 265.30 KB |

| Connection plan asynchronous motors | 09 | 441599 | 2018 01 | EN | 186.36 KB |

| Connection plan POWERBOX high-speed rectifier fitting in the terminal box | 04 | 441647 | 2011 04 | EN | 278.87 KB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| No results were found. | ||||||

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| EU declaration of conformity asynchronous motors and asynchronous geared motors | 12 | 441454 | 2020 11 | EN | 118.90 KB |

Take advantage of the expertise of our application engineers in the Sales Centers or contact our first level support.

OPENsystemsupport@stoeber.de

With SERVOsoft®, you have a tool at your fingertips that lets you design your drive systems with precise scaling in just a few steps. Electrical as well as mechanical design, and simple and fast at the same time.

OPENWith the intuitive STOBER product configurator, you can filter, compare, save and share the right drive solutions with ease.

OPENAre you looking for CAD data? With the STOBER CAD tool, the drawings you need are ready for download in just a few clicks.

OPENSTOBER is present in over 40 countries worldwide with 13 locations and 80 service partners. No matter where, no matter when, we’re always at your service and on the move!

OPENDo you need competent help with replacement parts, replacement drives, repairs and retrofitting? Feel free to contact us! We also offer a 24-hour hotline for urgent cases.

OPENSTOBER as a development partner.

“We are very satisfied with the result and we will keep relying on the professional support STOBER provides. Partnerships like ours with STOBER are a particular advantage for us in custom mechanical engineering because this requires very specific solutions.”

– Johannes Stocker, Electrical Systems Designer, e & v Systeme GmbH

We get your visions moving

in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

This might also interest you

Asynchronous Helical Bevel Geared Motors

Asynchronous helical bevel geared motors have impressively convenient installation dimensions, high efficiency and a good energy balance.

Asynchronous Offset Helical Geared Motors

Compact, absolutely robust, with high efficiency and an IE3-classified asynchronous motor. Ideal for industrial applications that have limited space.

Asynchronous Helical Geared Motors

This combination of a compact, economical helical gearbox and an IE3-class asynchronous motor for energy efficiency is a versatile jack-of-all-trades.